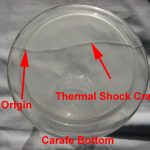

Glass is a brittle material, and it is not expected to fail from fatigue. To test this possibility, a borosilicate glass (i.e. low coefficient of thermal expansion) coffee was selected. The coffee pot bottom was scratched using a wet scrubbing pad It was then thermal “shocked” by heating it to 160° C and plunged […]

Failure Analysis of a “Exploding” Beer Bottle

California Glass Failure Expert performs a Root Cause Glass Failure Analysis on an “exploding” beer bottle.

Porcelain Toilet Tank Failure Analysis

A failure analysis was performed on a toilet tank that had caused water damage to a residence. This failure initiated at a hold down bolt hole. This tank was 14 years old. Originally it was proposed that thus porcelain failure was the result of a manufacturing defect. The root cause failure analysis shows that the […]

California Coating Expert Performs Failure Analysis of Epoxy Paint

A California coating expert was confronted with a municipal water tank with a rubbery epoxy coating. The complaint was that the epoxy paint was not properly mixed, and it had not cured properly. During the coating failure analysis, the study showed that the epoxy paint was aliphatic amine cured. In addition, the tank was painted […]

Grinding Wheel Failure Analysis

Failure analysis expert witness performed a failure analysis on a broken grinding wheel. This is part of a product liability case where it was claimed that the wheel broke apart during normal use and injured the user. Examination of the wheel showed that the wheel had been broken by someone clamping it and breaking off […]