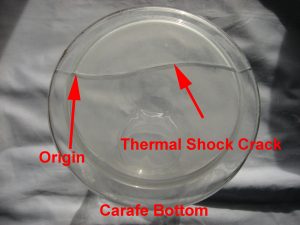

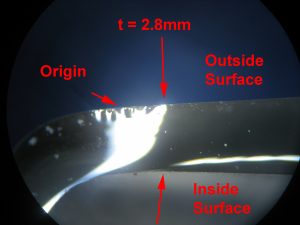

Glass is a brittle material, and it is not expected to fail from fatigue. To test this possibility, a borosilicate glass (i.e. low coefficient of thermal expansion) coffee was selected. The coffee pot bottom was scratched using a wet scrubbing pad It was then thermal “shocked” by heating it to 160° C and plunged into 10° C water. This was done numerous times till a crack was visible. One coffee pot failed after 55 cycles. Please see the photographs below.