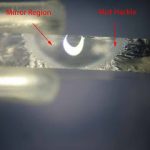

A California failure analysis expert has been testing the strength of beer bottles by causing them to fail from pressure overload. In all cases the origin always had a mirror region at the origin. The presence of the mirror region indicates that the crack initially grows slowly. Theoretically, the mist hackle indicates that the crack velocity has […]

Brass Plumbing Failure Analysis Stress Corrosion Cracking (SCC)

California failure analysis expert witness has analyzed numerous plumbing failures involving yellow brass (i.e. brass with more than 30% Zn in the alloy). The two major brass failure modes in yellow brass are dezincification and stress corrosion cracking. Above are two samples of stress corrosion cracking. Sress corrosion of yellow brass commonly involves the presence of ammonia along with the […]

Failure Analysis Expert Examines Bottle Failure

Glass failure analysis expert witness prepared numerous bottle failures of “off the shelf” 12 oz beer bottles by over-pressuring them with a hydraulic pump. These tests were needed to generate bottle failures of a known origin in order to examine the crack patterns, the fracture surfaces, and the failure origins. Numerous bottles were broken, and […]

Tempered Glass Expert Describes Failure Origin for Tempered Glass

Glass failure analysis expert demonstrates how to locate the origin of a tempered glass failure. Glass failure analysis of a tempered glass piece is difficult (if not impossible) because tempered glass fracture results in many small pieces. In many cases the glass failure falls apart and there is no pattern left to trace […]