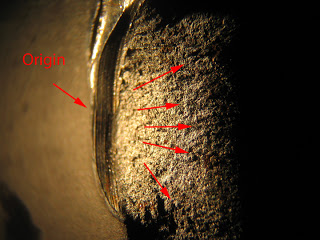

An interesting failure of steel tubing was observed when 1 3/4″ diameter A513 Type 5 steel tubing was being bent in a tubing bender. In this case the tube was clamped into the bender in the wrong location. At this time the clamp bolt had made an indentation (nick) in the pipe surface. The pipe was released and moved. The “nick” ended up on the tensile surface (i.e. convex side of the bend) during bending. As the tubing was being formed it broke in a ductile manner. A513 Type 5 steel is work hardened and therefore has little ductility, and it cannot survive bending if the surface has been damaged. The appropriate tubing should have been made of C 1020 mild steel. Upper left is a photograph of the nick on the convex side of the bend. The failure is interesting because it is a progressive failure that was caused by non-cyclic stresses (i.e. it is not metal fatigue). In addition, there are faint crack arrest lines that show the progression of the ductile failure. The failure surface almost looks like metal fatigue. This fsailure did not occur when C 1020 tubing was treated in the same manner. This failure was the result of improper material selection. It is not the result of a manufacturing defect.