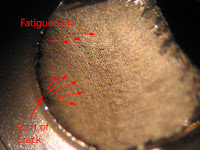

Read Consulting performed a metal failure analysis on two surgical screws that were used to hold wire for a surgical implanted back support system. These titanium screws failed after less than one year after the surgical implant.The failure analysis determined that both screws failed at the minor diameter due to metal fatigue in bending. In one case there was a machining mark that was associated with the initiation of the fatigue failure. This machining mark acted as a stress riser that magnified the applied stress. In addition, the bending stresses were higher on both screws because these titanium screws were not inserted completely.