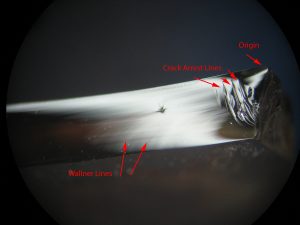

A glass chimney intended to hold a candle failed at the bottom, and injured the user. The glass chimney has several design defects. It is made with high thermal expansion soda lime glass (borosilicate glass is a better choice), and it is closed on the top (the top should be open to allow heat and smoke to escape). In addition, the chimney is placed on A steel base with a 3mm thick raised steel rim. This item is poorly designed. The bottom of the glass chimney can be damaged by banging on the raised rim (the rim should made from a compliant material to prevent damage to the glass when the chimney is placed on it). These design defects create a product liability. Glass failure analysis determined that the failure was initiated by impact on the chimney bottom. The remainder of the failure was driven by thermal stresses.