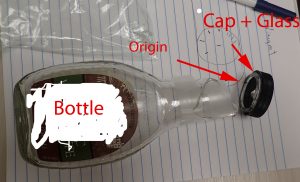

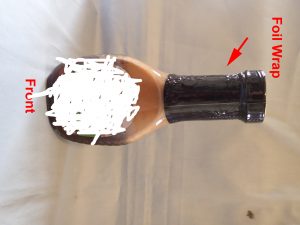

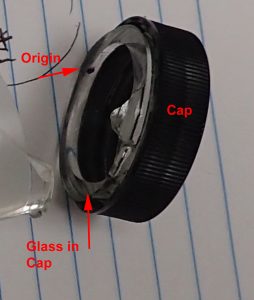

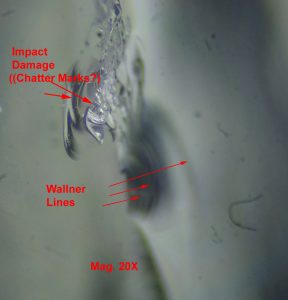

Read Consulting failure analysis laboratory performed a glass failure analysis of a broken of vinaigrette salad dressing bottle. The bottle top broke off when the top was being twisted off and injured the user. The integrity of the bottle neck was in question. There was a suspicion of a glass defect in the bottle neck (i.e. was there a manufacturing defect?). The overall crack was traced to its origin. At the failure origin there was glass damage. It appears as if this damage occurred when the foil around the cap was cut for removal. If the foil cutting is too aggressive. the neck can be damaged, and this creates a small crack. The force applied to the neck when removing the cap can cause this crack to grow and cause the bottle neck to shear off. Below is a series of photographs showing the steps of the failure analysis. In this analysis, the crack was traced back to the origin. Chatter marks and other glass damage was found at the origin. This damage occurred after the bottle was made. The most likely explanation is that it was caused by cutting the foil. There is no manufacturing defect.

Or… there was a bacterial buildup in the bottle producing a gas buildup. When the cap was twisted just a tiny but it allows the pressure to be release therefore causing the top to exploded. It’s not the first time this has happened.

Wish I could post pictures of my sister’s palm and her twelve stitches.

Positive pressure would make the cap easier to remove.