Read Consulting was engaged to examine a failed polypropylene (PP) lawn chair used poolside in a desert environment. In this type of environment, air temperatures can reach higher than 110°F.

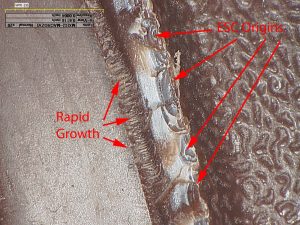

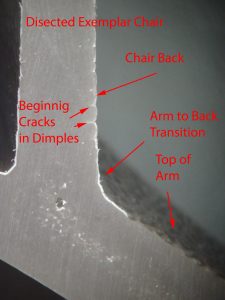

This means the surface of a dark chair can reach temperatures higher than 150°F. Previous studies on polypropylene plumbing failures have shown that hot chlorinated water (at approximately 140°F and higher) will degrade polypropylene (PP) piping and cause environmental stress cracking (ESC). The degraded PP turns white and becomes weak and brittle. For this chair, the chlorinated water comes from the spa and pool. It collects in dimples in the chair surface where it is heated in the sun.

The subject Polypropylene (PP) chair failed initially because of chemical attack of the PP from hot chlorinated pool and spa water. The rough PP surface (i.e., dimpled) allows pool and spa water to puddle on the surface. The combination of bending stress and the hot chlorinated water in the desert sun created the conditions of mechanical, chemical attack of the PP where the chair arm transitions to the chair back. This is environmental stress cracking of polypropylene.

After the initial arm failure, the chair back collapsed due to a series of brittle failures of the PP on the back webbing and the opposite arm.