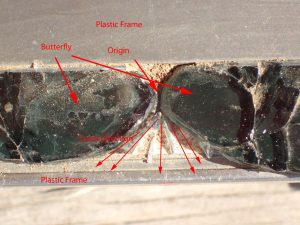

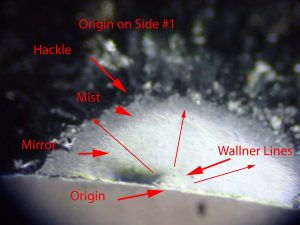

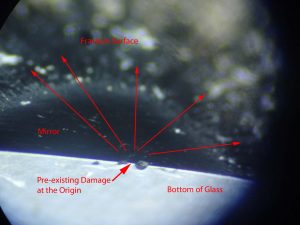

Traditionally, a top loading clothes washer has a steel top. This means that a person can safely put part of their weight on the washer top. Recently, some manufacturers have replaced the steel top with a piece of tempered glass (on the order of 1/8” thick) darkened on the bottom with a glass frit coating . A tempered glass top creates the possibility that the washer top cannot support a load and is prone to shattering when a user puts part of their weight on it. In this case, the owner was kneeling on the glass appliance top and went through the glass causing an injury. Fortunately, the failure origin remained glued to the plastic frame; this allowed a glass failure analysis to be performed. The resulting tempered glass failure analysis is described below. This washer lid failed from of bending that initiated a failure in the bottom where there was localized mechanical damage.