|

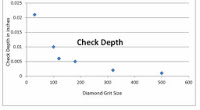

| Chart Showing Damage Depth of Diamond Grind v. Diamond Particle Size |

|

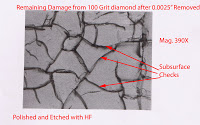

| Checks in Glass Revealed by Etching with Buffered HF |

|

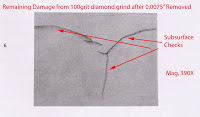

| 100 Grit Damage Remaining After 0.0075″ Had Been Removed |

Certain types of glass must be ground to shape with a diamond tool, and they are then lapped and polished to make them transparent. If this glass piece must also exhibit a certain strength level, each subsequent finishing step must remove all the damage from the previous step. These considerations dictate tool design and diamond grit size selection. The chart above shows that damage depth from diamond grinding is directly related to the size of the diamond abrasive Note: As the grit size number increases, the abrasive size decreases). The nature of subsurface damage from a 100 grit diamond are shown in the other two 390 X photo micro-graphs. These pieces were polished to be optically clear; they were then etched with a buffered HF solution. Etching highlighted the damage remaining from the diamond grind. Even after 0.0075″ had been removed, there was remaining subsurface damage. This remaining grind damage significantly weakens the glass. Thus, it must be completely removed for reliable mechanical properties.