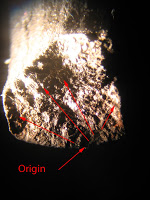

A California failure analysis expert performs a failure analysis on a broken water flow indicator. This flow indicator was in a large building, and as a result of the failure, there was substantial damage. The flow indicator consisted of a glass dome clamped into a metal housing.The failure originated where the flange of the glass dome contacts the interior wall of the metal housing. The failure initiated at the “half thickness” of the flange on the glass dome and spread left and right. This failure was caused by misalignment of the glass dome with respect to the interior of the glass housing. From this perspective, this is an assembly defect. From another perspective, this is a design defect. The absence of a compliant spacer between the edge of the flange and the wall of the metal housing allows misalignment. A design improvement would be to add a compliant “ring” spacer between the glass dome flange and the interior wall of the metal housing. This failure should be considered a product defect.

Materials Failure Analysis and Process Engineering

You are here: Home / Failure Analysis / Plumbing Failure Analysis: Failure Analysis of a Water Flow Indicator

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.