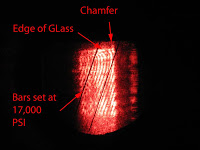

California glass expert uses a grazing angle surface profilometer (GASP) to study the compressive stresses at the edge of a tempered glass oven door. The edge effects during the air quench step of the thermal temper process are said to lower the surface stress to zero near the edge of the glass article. In fact, fragmentation tests of tempered glass pieces yield a “picture frame” around the edge of the part. Fir this reason, a GASP was used to examine surface stress at the edge. Upper left is an image of the GASP interference pattern in the center of a tempered glass toaster oven door. The surface compressive stress measures 17,000 psi. Upper right is a similar image measured near the edge of the part. In this region the fringes curve, and they show the surface stress going to zero. This is important because any damage to the glass in this region of reduced surface compression stress is more likely to cause failure.