Read Consulting, a glass failure analysis laboratory, was hired to analyze defective glass bottles. These bottles arrived from the manufacturer with defects. Because only still wine is to be bottled, none of the defects discovered can cause cracking. Below are details of the two prevalent bottle defects from the glass bottle manufacturer.

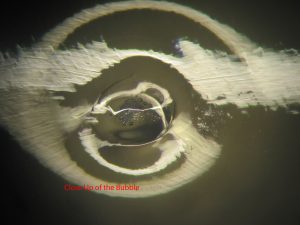

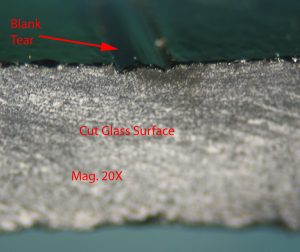

Blank Tear

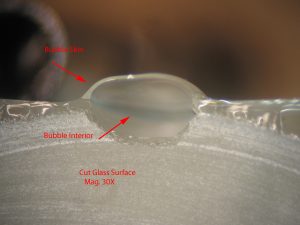

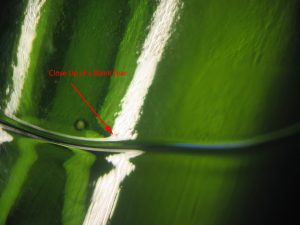

Bubble