Read Consulting glass experts were asked to determine the root cause of window failures at a recently built hotel. Over the period of two to three years, the windows began to appear as if they were dirty with a swirly pattern. Attempts to clean off the “dirt” were unsuccessful. As a result a number of these windows on the south elevation were replaced. Over time these replacement windows also displayed the subject defect. Read Consulting was asked to characterize the window defect and to assess the extent of the problem (i.e. how many of the windows were defective).

Results Summary

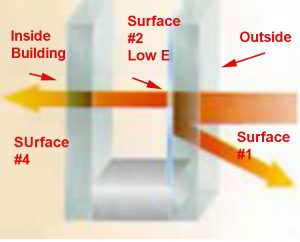

The window defect was the failure of the Low E coating on surface 2 (see Figure #1) on the interior of the dual pane structure of the window. This is a manufacturing defect and is not a result of post installation cleaning damage. The defect is so severe that these windows cannot pass ASTM 1036 window requirements for Architectural glass. This resulted that 100% of the hotel windows are affected and all these windows must be replaced.

Procedure

This effort has two parts:

Part One:

Determine the Nature of the Defect:

An exemplar defective window was shipped to Read Consulting for evaluation. This window was evaluated visually and with a low power microscope. In addition, the “outside” glass panel was removed from the dual panel structure. Surface #2 was then examined directly with a low power microscope. In addition, a plastic “scraper” was used to remove portions of the soft E-Coating on surface #2.

Part Two:

Determine the Extent of Damage:

Determine How Many of the Windows at are Affected. In order to determine how many windows were affected, time was spent viewing and photographing representative windows all around the hotel. The West and North Sides of the hotel were examined on day 1, and the East and South sides of the hotel were examined on day 2.

Determine if this Defect Would Pass ASTM C 1306- 06:

The tests described and recommended by ASTM C 1306 – 06 were performed on several windows from the interior of the hotel rooms. These windows were examined while illuminated by and transmitting diffuse light. The severity of the defect was recorded.

Figure #1: Representative demonstration of a dual pane thermal control window with a Low E coating. The surfaces are numbered from #1 (the outdoor surface) through #4 (the indoor surface).

Results

Nature of the Damage

Examination of Exemplar Window Sent to Read Consulting

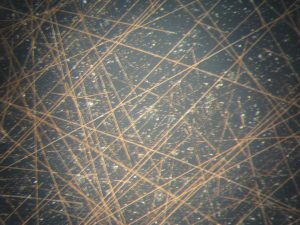

Figure #2: Photomicrograph of the defect as observed through the glass from surface #1. The defect appears to be some sort of scratching on surface #2 (Mag. 40X).

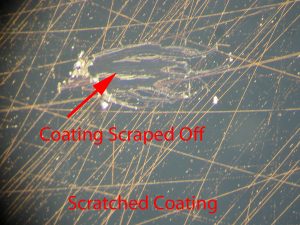

Figure #3: Photomicrographs of the defect as observed directly on the exposed surface #2. On the left is the defect and it appears to be some sort of scratching. The photo on the right is after the low E coating has been scraped off. The defect is contained in the Low E coating on surface #2. It is not scratching of the glass. This means that there is a defect in the Low E coating that looks like scratching but worsens with time. The fact that the defect is on a surface interior to the dual pane structure demonstrates that the defect was created in the manufacturing process and is not a result of post installation window cleaning (Mag. 40X).

Extent of the Damage

Number of Windows

All four elevations were viewed to determine the appearance of the damage and to determine the percentage of windows affected. The defect in question was discovered because the windows appeared dirty and could not be cleaned. The windows show a defect that appears as “a swirly dirty contaminant.” However, as stated before, cleaning the windows had no effect on the defect. The site inspection revealed that all of the windows are affected. This includes the replacement windows on the south elevation.

ASTM C1306 Test Results

ASTM C 1036- 06 Standard Specification for Flat Glass

The subject window defect eventually becomes bad enough that it can be seen (per the illumination requirements of ASTM C1306) at a distance of 160 inched when viewed on the normal while transmitting diffuse light. The defect is an array of medium to heavy linear defects and therefore, none of these windows would qualify as architectural grade windows per ASTM C1036.

Figure #4: Photograph of a defective window taken from inside the room with incident diffuse light. The array of linear defects is visible as far as 160 inches from the window. Because of these defects, the glass in this window disqualifies it as suitable for architectural glass.

This exact same thing just happened to our very large windows that face West. We thought it was scratches from cleaning and now we think it’s a glass defect. The manufacturer won’t help us. We are so upset.

We purchased a new construction home last year and are upon the 1-year warranty. Several windows showed the discoloration because of the breakdown of the Low-E coating. This only happens if the seal has failed. I used a can of “air” upside down to freeze the outer surface of the window which caused condensation between the window panes on the known broken seal windows. I checked all my other windows and over half had the same issue but did not show any visible signs of a seal failure. The home builder and window manufacture say there is only a visual test to determine if a window seal has failed. I believe that the test I conducted is accurate to determine if there is any moisture and outside air that has displaced the Argon gas. Do you have another approved or certified test that could be done so the windows can be replaced now by manufacturer rather than at my cost a few years down the road?