Introduction

Read Consulting LLC performed an “early morning” inspection on the windows of a library of a Community College. The subject damaged windows were inspected while still installed. Thus, window damage visibility was dependent on the angle of the light during the inspection. The damage is much more visible in direct sunlight; therefore the windows on the east side of the building were used as representatives of the overall window damage. This is a result of the inspection being performed in the early morning.

It is important for the reader to understand how improper cleaning can scratch a window surface. In almost all cases, dust or grit consists mainly of silica particles (i.e. SiO2). Window glass (which is “soda lime glass”) 72% SiO2, 15% Na2O and 13% CaO, is readily scratched by silica dust. This occurs on both tempered and non tempered glass. Therefore, window cleaning must be done carefully with lots of the proper window cleaning solution and soft tools (see Appendix ‘A’). The windows should be “soaked in the solution before any wiping is done. This is particularly true for windows on new construction. These windows are normally very dirty, and they also may have stucco, mortar, spackle or concrete splatter on them. All of these materials are extremely hard and can be bonded chemically to the glass. During cleaning these materials can break free and cause scratching. Appendix ‘A’ was published by the Glass Association of North America. Cleaners must follow the techniques that it describes to the letter if good results are to be obtained.

Summary Conclusion

The window damage was caused by improper window cleaning procedures. This damage is not a result of a manufacturing defect. Appendix A contains proper window cleaning procedures suggested by the Glass association of North America (GANA).

Inspection Procedure

The windows were inspected for scratches visually. Numerous macro-photographs were taken to document the window cleaning damage. Because the visibility of window damage scratches depends strongly on the ambient lighting conditions, representative photographs were taken of those windows that had the proper lighting to reveal the damage found.

Objective

Assess the level of window scratching at a community college library and determine the cause of the window damage.

Procedure

- Inspect and document with photographs the damage to the windows installed at the library.

- Perform the inspection for linear defects described in ASTM C1036 on a representative window submitted to window failure analysis expert.

Site Inspection

Introduction

Due to the available ambient lighting, the windows on the east side of the building were the main focus of the inspection. Windows on the other three sides showed identical damage; however, it was much more difficult to photograph the damage on them. The inspection showed that the damage to the windows was window cleaning damage. Numerous windows showed cleaning damage. In the future, the exact number of damaged windows should be determined with a thorough survey.

Site Inspection Photographs

Below are some representative photographs of the damage found on the windows at the site. Many more photographs were taken, and these are available upon request. All the window damage observed and documented was caused by cleaning.

Figure #1: Photograph of the east side of the Community College Library. This photograph was taken in the morning and one can see the shadows formed by the newly risen sun.

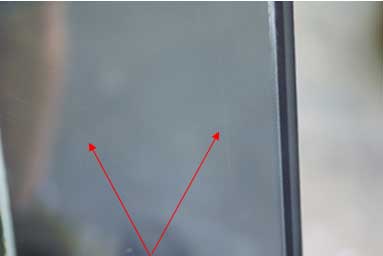

Figure #2: Photograph from the building interior of one of the east facing windows of the library. The damage to the window in the center of the photograph is easily seen. This type of damage is typical of window cleaning damage. In this case, a blade was used on this window, and it created a series of parallel scratches. These are created when grit particles get caught under the blade and are dragged across the glass surface during cleaning.

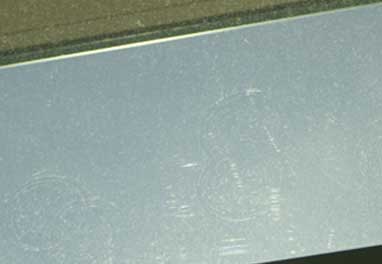

Figure #3: Close up photograph of the window damage shown in Figure #2. There are several sets of “sweeping” parallel cleaning scratches created when a metal blade was used to scrape the window. With the right angle of light, these scratches really “light up”.

Figure #4: Close up photograph of another damaged window. Again, there are several sets of parallel cleaning scratches created when a metal blade was used to scrape the window. In addition, one can see circular marks left by the rubber tools used by the glazers to handle the glass. Not only does this window have cleaning scratches, it hasn’t even been properly cleaned after installation.

Figures #5 and #6: Examples of more cleaning damage to the windows of the library.

Results of ASTM C 1036 Evaluation

Normally this test is performed in the factory to assess the quality of flat glass. It is used here as a “severity check” on the quality of installed windows.

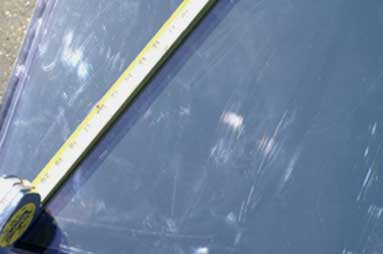

Figure #7: Macro-photograph of several linear defects seen on the subject glass under the test lighting conditions. This photograph was taken at a distance of 140”. Several linear defects longer than 12”are clearly visible. These are in the “severe damage” category of ASTM C1036.

Figure #8: Photograph of the same linear defects seen on the subject glass under direct lighting conditions. One can see that the damage is severe. This is all cleaning damage.

Appendix A

Glass Informational Bulletin #01-0300 from the Glass Association of North America

Proper Procedures for Cleaning Architectural Glass Products

Architectural glass products play a major role in the comfort of living and working environment of today’s homes and commercial office spaces. By providing natural daylight, views of the surroundings, thermal comfort and design aesthetics, glass usage and condition often affect our selection of where we live, work, shop, play and seek education. Architectural glass products must be properly cleaned during construction activities and as a part of routine maintenance in order to maintain visual and aesthetic clarity. Since glass products can be permanently damaged if improperly cleaned, glass producers and fabricators recommend strict compliance with the following procedures for properly cleaning glass surfaces. As dirt and residue appear, interior and exterior glass surfaces should be thoroughly cleaned. Concrete or mortar slurry which runs down (or is splashed on) glass can be especially damaging and should be washed off as soon as possible. Before proceeding with cleaning, determine whether the glass is clear, tinted or reflective. Surface damage is more noticeable on reflective glass as compared with the other glass products. If the reflective surface is exposed, either on the exterior or interior, special care must be taken when cleaning, as scratches to the reflective glass surface can result in coating removal and a visible change in light transmittance. Cleaning tinted and reflective glass surfaces in direct sunlight should be avoided, as the surface temperature may be excessively hot for optimum cleaning. Cleaning should begin at the top of the building and continue to the lower levels to reduce the risk of leaving residue and cleaning solutions on glass at the lower levels. Cleaning procedures should also ensure that the wind is not blowing the cleaning solution and residue onto already cleaned glass.

Cleaning during construction activities should begin with soaking the glass surfaces with clean water and soap solution to loosen dirt or debris. Using a mild, non-abrasive commercial window washing solution, uniformly apply the solution to the glass surfaces with a brush, strip washer or other non-abrasive applicator. Immediately following the application of the cleaning solution, a squeegee should be used to remove all of the cleaning solution from the glass surface. Care should be taken to ensure that no metal parts of the cleaning equipment touch the glass surface and that no abrasive particles are trapped between the glass and the cleaning materials. All water and cleaning solution residue should be dried from window gaskets, sealants and frames to avoid the potential for deterioration of these materials as the result of the cleaning process. It is strongly recommended that window washers clean a small area or one window, then stop and examine the surface for any damage to the glass and/or reflective coating. The ability to detect certain surface damage, i.e. light scratches, may vary greatly with the lighting conditions. Direct sunlight is needed to properly evaluate a glass surface for damage. Scratches that are not easily seen with a dark or gray sky may be very noticeable when the sun is at a certain angle in the sky or when the sun is low in the sky.

The glass industry takes extreme care to avoid glass scratches by protecting all glass surfaces during glass manufacturing and fabrication, as well as during all shipping and handling required to deliver the glass to the end user. A large percentage of damaged glass results from non-glass trades working near glass. This will include painters, spacklers, ironworkers, landscapers, carpenters and others who are part of the construction process. They may inadvertently lean tools against the glass, splash materials onto the glass and/or clean the glass incorrectly, any of which can permanently damage glass. One of the common mistakes made by non-glass trades people, including glass cleaning contractors, is their use of razor blades or other scrappers on a large portion of the glass surface. Using 2, 3, 4, 5 inch and larger blades to scrape a window clean carries a large probability for causing irreparable damage to glass. The entire industry of glass manufacturers, fabricators, distributors, and installers neither condones nor recommend widespread scraping of glass surfaces with metal blades or knifes. Such scraping will often permanently damage or scratch the glass surfaces. When paint or other construction materials cannot be removed with normal cleaning procedures, a new 1″ razor blade may need to be used only on non-coated glass surfaces. The razor blade should be used on small spots only. Scraping should be done in one direction only. Never scrape in a back and forth motion as this could trap particles under the blade that could scratch the glass. This practice may cause hairline concentrated scratches, which are not normally visible when looking through the glass, but may be visible under certain lighting conditions. Jobsite storage and construction conditions can lead to stains on the glass surface. Cleaning and removal of such stains may require the use of a more aggressive cleaning solution and procedure. If conditions are found that cannot be cleaned using the above procedures, contact the glass supplier for guidelines on stain removal.

Members of the Glass Association of North America (GANA) publish information relating to jobsite protection and cleaning of architectural glass products. In order to ensure long-term performance of the glass in a building, GANA encourages glazing contractors, general contractors, building management and owners to be aware of conditions that can damage glass and to follow the handling and cleaning guidelines provided by their glass producer and fabricator. Consult the GANA website (www.glasswebsite.com) for additional information on glass and glazing applications and links to members providing additional technical resources. The Glass Association of North America (GANA) has produced this Glass Information Bulletin solely to provide general information as to basic proper procedures for cleaning architectural glass products. The Bulletin does not purport to state that any one particular type of glass cleaning process or procedure should be used in all applications or even in any specific application. The user of this Bulletin has the responsibility to ensure the cleaning instructions from the glass supplier are followed. GANA disclaims any responsibility for any specific results relating to the use of this Bulletin, for any errors or omissions contained in the Bulletin, and for any liability for loss or damage of any kind arising out of the use of this Bulletin.

Quick-Reference Guide to Cleaning Architectural Glass Products

The following “Do’s” and “Do Nots” are offered as a supplement to the Glass Association of North America (GANA) Glass Informational Bulletin – Proper Procedures for Cleaning Architectural Glass Products:

The following are things to DO:

- – DO clean glass when dirt and residue appear

- – DO determine if coated glass surfaces are exposed

- – DO exercise special care when cleaning coated glass surfaces

- – DO avoid cleaning tinted and coated glass surfaces in direct sunlight

- – DO start cleaning at the top of the building and continue to lower levels

- – DO soak the glass surface with a clean water and soap solution to loosen dirt and debris

- – DO use a mild, non-abrasive commercial window cleaning solution

- – DO use a squeegee to remove all of the cleaning solution

- – DO dry all cleaning solution from window gaskets, sealants and frames

- – DO clean one small window and check to see if procedures have caused any damage

- – DO be aware of and follow the glass supplier’s specific cleaning recommendations

- – DO caution other trades against allowing other materials to contact the glass

- – DO watch for and prevent conditions that can damage the glass

- – DO read the entire GANA bulletin on glass cleaning before starting to clean glass

The following are things to NOT do:

- – DO NOT start cleaning without reading the entire GANA bulletin on glass cleaning

- – DO NOT use scrapers of any size or type for cleaning glass

- – DO NOT allow dirt and residue to remain on glass for an extended period of time

- – DO NOT begin cleaning glass without knowing if a coated surface is exposed

- – DO NOT clean tinted or coated glass in direct sunlight

- – DO NOT allow water or cleaning residue to remain on the glass or adjacent materials

- – DO NOT begin cleaning without rinsing excessive dirt and debris

- – DO NOT use abrasive cleaning solutions or materials

- – DO NOT allow metal parts of cleaning equipment to contact the glass

- – DO NOT trap abrasive particles between the cleaning materials and the glass surface

- – DO NOT allow other trades to lean tools or materials against the glass surface

- – DO NOT allow splashed materials to dry on the glass surface

This bulletin was developed by the GANA Tempering Division – Construction Subcommittee and approved by the Tempering Division – Standards & Engineering Committee and GANA Board of Directors. This is the original version of the document as approved and published in March 2000.