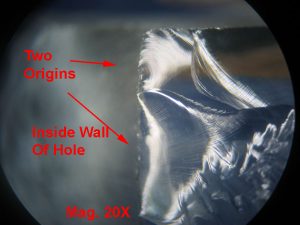

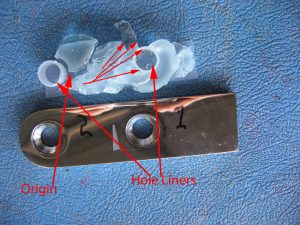

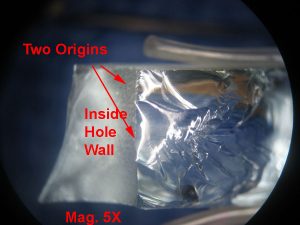

A tempered glass shower door failed. Read Consulting was asked to determine the cause of failure. The door hung from a rail on two rollers. The glass is suspended by four holes in the glass through which 4 bolts are inserted. Each bolt was properly isolated from the glass by plastic inserts. Even so, the glass failure originated at one of the holes. It is important to note that there are numerous starting cracks created by the grinding process used to create the holes in the glass. It is believed that the forces associated with either opening or closing the door were high enough to activate two of the grinding cracks and cause failure. Once the damage penetrates into the tempered glass core, cracks will spread through the glass at 3400mph. The attached figures demonstrate these findings