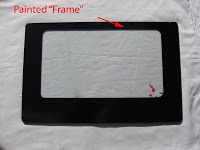

Glass experts at Read Consulting performed a glass failure analysis on several fully tempered glass oven doors that failed in an unexpected manner during thermal shock testing. 100% of these doors failed the glass thermal shock test. The subject tempered glass doors were painted

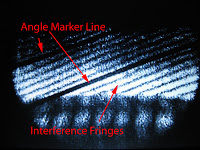

with a 20µ thick picture frame on one side (top left photo). Using a Strainoptics grazing angle surface profilometer (GASP), the temper stress for all the doors tested (i.e. before thermal shock testing); all doors measured to have surface compression stresses in excess of 13,000 psi. In the upper right photograph is a typical GASP output for these doors. Therefore one would expect the failure mode to be “dicing”.In fact, all the failures initiated with long thermal

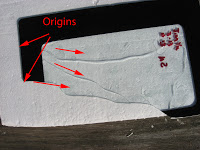

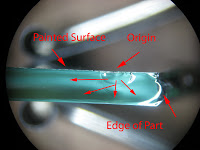

cracks. Only in the later stages of failure did portions of the doors break into small pieces (i.e. dice). A typical failure is shown in the lower left photo. A typical failure origin is shown in the lower right photograph. The failures initiated under the paint. This indicates that, during thermal shock, tensile stresses were created at the paint-glass interface that overcame the tempered glass compressive surface stresses and initiated a crack. These painted tempered glass oven doors had a 100% failure rate; Identical unpainted doors had a 100% survival rate.