|

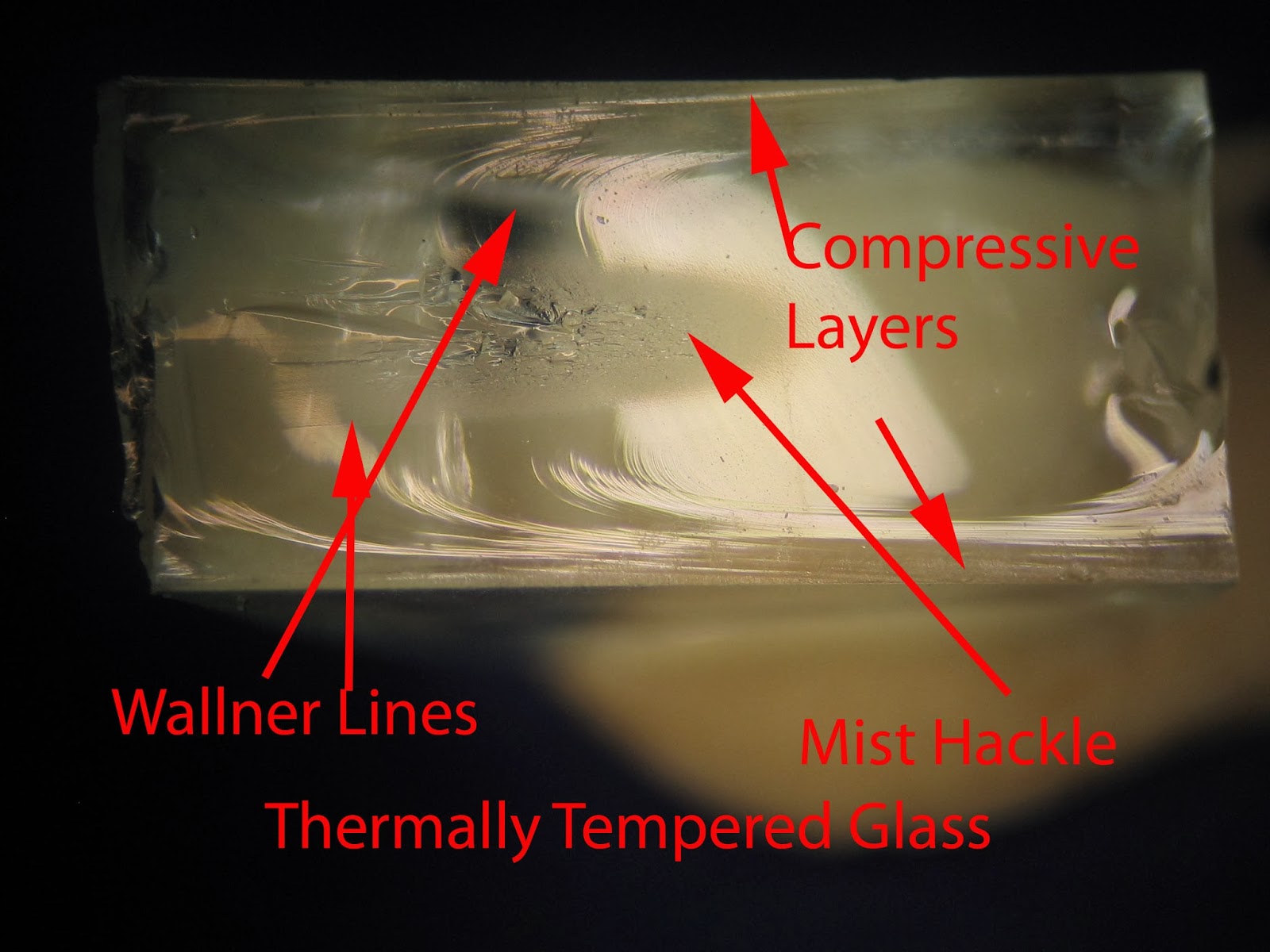

| Fracture Surface of Thermally Tempered Glass |

|

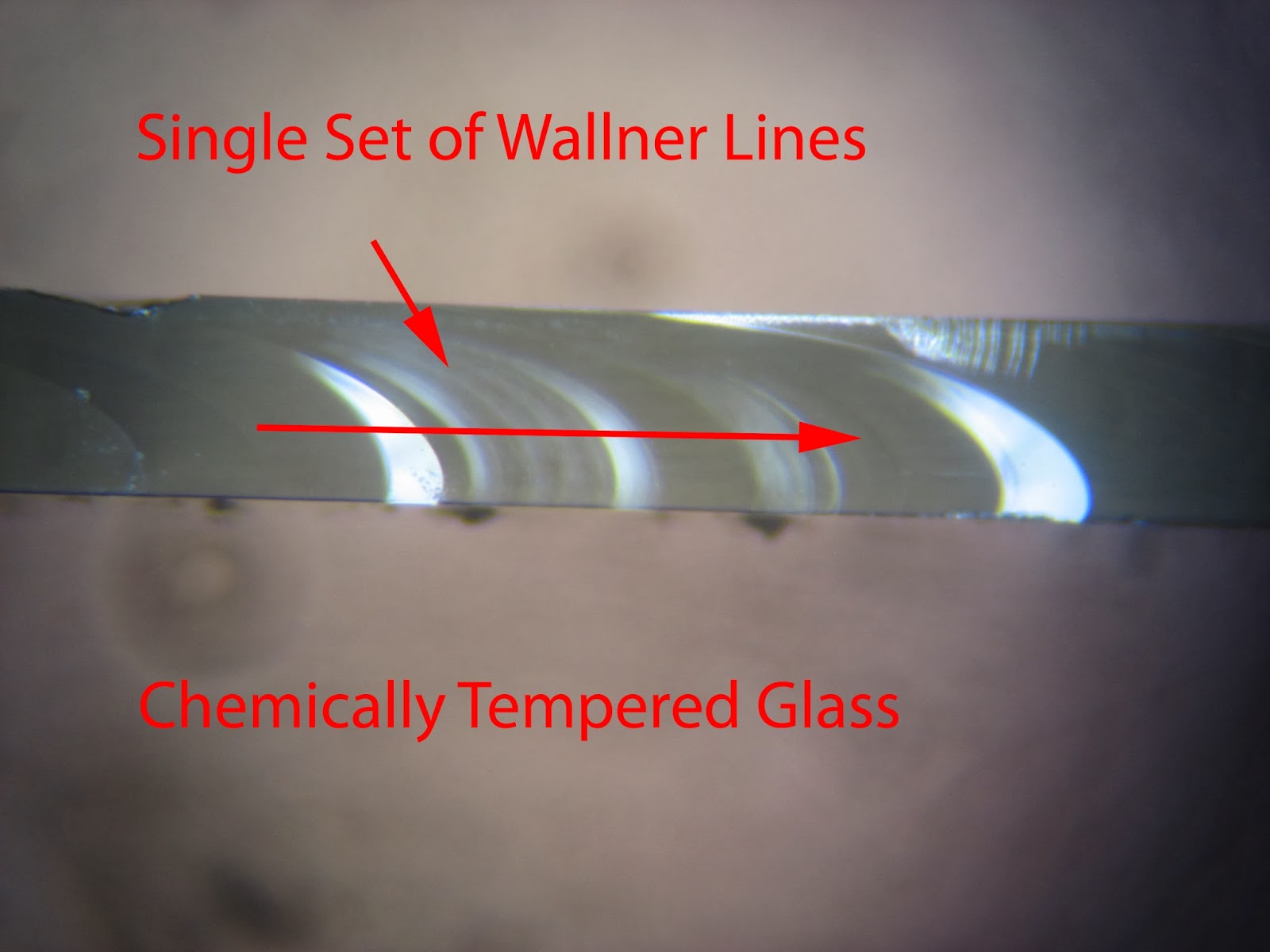

| Fracture Surface of Chemically Tempered Glass |

The Glass Expert Witness at Read Consulting have performed hundreds of glass failure analysis on tempered glass pieces. These include both thermally tempered and chemically tempered glass.

Thermally tempered glass has compressive stress on its surfaces. The thickness pf the compressive layer is a function of the over all glass thickness; this thickness is 20% of the glass thickness. In addition, the resulting fracture surface of thermally tempered glass has distinct characteristics. There are two sets of Wallner lines (which indicate the crack travel direction) separated by a band of mist hackle. In addition, near the surfaces there are parallel markings indicating the surface compressive stresses.

Chemically tempered glass also has its surfaces in compression. For this glass, the compressive layer is very tin; it is on the order of 10µ’s. In addition, this thickness is not a function of the glass thickness. It is dictated by the chemical tempering process. Because the compressive layer is so thin, there are no distinct markings on the fracture surface. Often the fracture surface is featureless, or it will have a single set of Wallner lines indicating the direction of travel.