There are two dominant modern tile types made for showers and swimming pools. These are glazed ceramic tiles and glass tiles. In these applications the tiles are exposed to thermal shock. Theoretically both tile types perform the same function. So it is important to understand the expected level of resistance to thermal shock for these two types. Below are listed the requirements for each type:

Porcelain tile are expected to pass thermal shock requirements listed in both ASTM C484 and ISO 10545. The tiles are cycled 10 times between temperatures of 15°C and 150°C. The tiles are removed from a 150°C oven and “doused” in 15°C water. They are then put back in the oven. This is repeated 10 times. The temperature difference is 135°C.

Glass tiles are expected to pass the thermal shock test requirements described in ANSI A 137.2-2013. The tiles are cycled 10 times between temperatures of 15°C and 71°C. The tiles are removed from a 71°C oven and “doused” in 15°C water. They are then put back in the oven. This is repeated 10 times. . The temperature difference is 56°C. This test is much less severe than that for glazed ceramic tile.

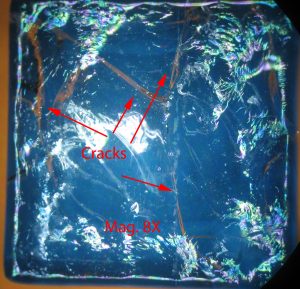

Why is there such a difference in the severity of the thermal shock? The obvious answer is that the glass tiles are not as robust. Both tiles perform the same function. Obviously porcelain tile is the safer choice. In fact, Read Consulting has performed numerous glass failure analyses on glass tiles installed in swimming pools. The cause of failure has always been thermal shock.

Be cautious when selecting tiles for your shower or swimming pool!