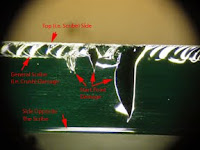

Glass expert describes the condition of the edges of windows, mirrors and other flat glass pieces. Almost all flat glass pieces are shaped from larger pieces using glass scribe and break techniques. Thus the edge of the part has two distinct sides. The photograph above is a microscopic picture of a the edge of an automobile mirror that was shaped in automatic scribing machinery. The top of the photomicrograph is the surface where the scribing tool has created controlled glass damage (i.e. crush). In general the damage is uniform. This photo incorporates start of the glass scribing, and this point always has more significant damage. Glass failure analysis determined that glass cracking due to thermal stresses initiated at the start point. Glass fracture analysis indicates that glass cracking always starts at the weakest point under tensile stresses.

Glass expert describes the condition of the edges of windows, mirrors and other flat glass pieces. Almost all flat glass pieces are shaped from larger pieces using glass scribe and break techniques. Thus the edge of the part has two distinct sides. The photograph above is a microscopic picture of a the edge of an automobile mirror that was shaped in automatic scribing machinery. The top of the photomicrograph is the surface where the scribing tool has created controlled glass damage (i.e. crush). In general the damage is uniform. This photo incorporates start of the glass scribing, and this point always has more significant damage. Glass failure analysis determined that glass cracking due to thermal stresses initiated at the start point. Glass fracture analysis indicates that glass cracking always starts at the weakest point under tensile stresses.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.