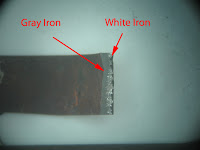

Failure expert performs a failure analysis on a cracked drain pipe removed from a high rise building. The pipe drained rainwater from the roof down to the ground This 2 3/4″ OD cast iron pipe began to fail after approximately 12 years of service. The upper left photo is an overview of a piece of the pipe. The predominant failure mode is a single linear crack parallel to the pipe axis. The crack opening is 1/4″ wide, and this opening indicates that there are residual tensile stresses in the pipe that are contributing to the failure. The photograph on the right show the fracture surface created when a section of the pipe is broken open. The outer layer of the pipe is white cast iron, and the interior portion of the pipe is gray cast iron. It is believed that because the outer portion of the pipe is chill cast, there are high residual casting stresses that are driving this stress corrosion failure.