Introduction

Read Consulting LLC to perform a root cause failure analysis on a collapsed 40,000 gallon bolted steel water storage tank located on the California coast.

Results Summary

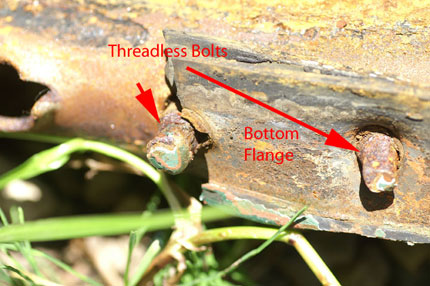

Corrosion is the root cause of the tank failure. The failure originated at the bottom of the tank on the West side. The initial failure resulted from corrosion on bolts holding the side of the tank to the mating flange on the tank bottom; these bolts had no remaining threads. Once this corrosion failure initiated, forces on the bottom and side walls increased, and other failure modes occurred. These include pulling nuts through the steel plate and tearing of the 12 gauge steel plates used to build the tank. One could describe this as a chain reaction failure initiated where bolts holding the bottom to the side wall failed as a result of the fact their threads had completely corroded off.

These “bottom” bolts were buried in gravel, and because of the costal location, there is a high level of salt in the moist gravel.

Finally, this tank is at least 47 years old. The manufacturers of these tanks only guarantee them for 20 years.

This failure indicates that steel water tanks have a limited lifetime when exposed to coastal weather.

Figure #1: Photograph of the West side of the failed tank. This is the site of the initial failure. The location of the failure origin is indicated by the arrow.

Figure #2: Photograph of the East side of the failed tank. This is opposite side of of the initial failure. When the tank opened the west side was no longer supported and the tank collapsed in a westward direction and the East side bent and lifted on the bottom.

Figure #3: Photograph of bolts on the bottom of the tank in the region of the failure origin. These bolts attach the side plate to a flange on the bottom of the tank. These particular bolts have no thread on them. Therefore, the joint strength in this location is negligible. Thus, the initial failure is separation of the side wall from the bottom, and it occurred here. After the failure initiated here, there was a chain reaction (i.e. the tank” unzipped” and tore apart. All this resulted from corrosion of the bolts.

Figure #4: A bolt that is near those seen in Figure #3. In this case the nut stayed on the bolt, but the plate stretched around the nut and pulled away.

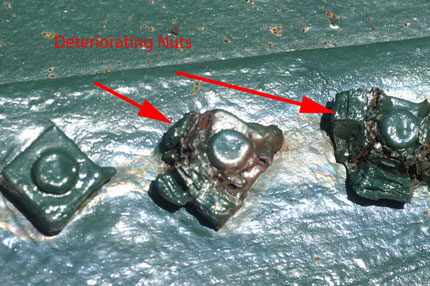

Figure #5: Photograph of other nuts on the tank. One can see that, even though the tank exterior gats periodic painting, the nuts show major deterioration.