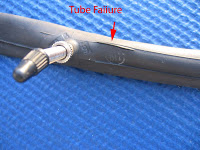

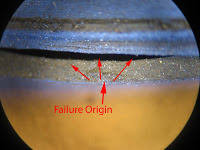

California failure analysis lab performs rubber failure analysis on a failed bicycle inner tube. The rider was braking while descending a long steep hill. Toward the bottom of the hill his inner tube failed, and he heard a loud pop. The wheel rim was too hot to touch. A failure analysis was performed and the failure originated at a point on the tube that would have been in contact with a spoke “nut”. It is believed that the tube was heated to the highest temperature at this location, and it softened to the point of failure. In addition, the tire pressure was elevated due to the heating of the rim from the friction of the brake pads. Upper right is a 40X photo-micro graph of the failure origin.

California failure analysis lab performs rubber failure analysis on a failed bicycle inner tube. The rider was braking while descending a long steep hill. Toward the bottom of the hill his inner tube failed, and he heard a loud pop. The wheel rim was too hot to touch. A failure analysis was performed and the failure originated at a point on the tube that would have been in contact with a spoke “nut”. It is believed that the tube was heated to the highest temperature at this location, and it softened to the point of failure. In addition, the tire pressure was elevated due to the heating of the rim from the friction of the brake pads. Upper right is a 40X photo-micro graph of the failure origin.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.