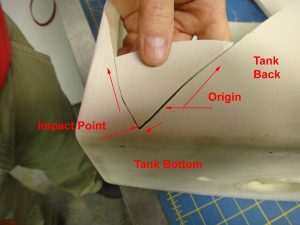

Tank as received Approximate Origin

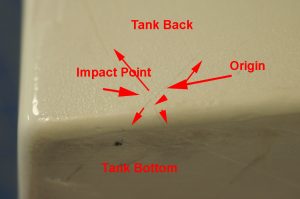

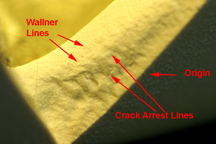

Impact Point Wallner Lines at the Origin

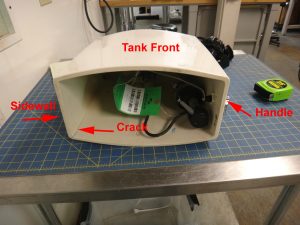

After a porcelain toilet tank failed, Read Consulting performed a root cause failure analysis. The toilet tank failed as a result of impacts to the backside of the tank near the lower right corner of the tank. This was determined by porcelain failure analysis. The tank was pulled apart to expose the fracture. Oblique lighting was used to follow the Wallner lines back to the origin. The tank was hit on the backside. This can occur when someone “large” sits down hard and leans back at the same time. In the UK the tanks are bolted to the wall, and this cannot happen. In the US there is a gap between the tank back and the wall. This allows for impact as a result of movement.