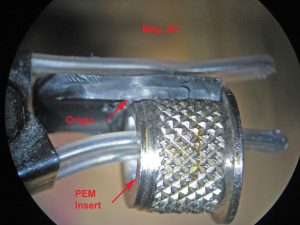

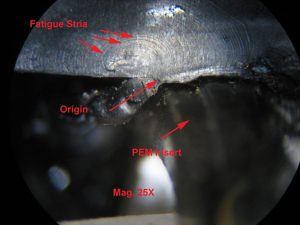

Read Consulting was asked to perform plastic failure analysis on a broken pickup truck tailgate latch. Attached are a series of photographs demonstrating the latch and the cause of failure. The latch is mostly held to the back gate with two machine screws that are screwed into PEM inserts pushed into bosses when the plastic is still hot. Over time the flexing of the steel PEM insert in the plastic boss generated fatigue cracks at the sharp edge of the bottom of the insert. This is a typical plastic failure created by the stiffer steel insert applying forces to the weaker plastic receptacle. Often the result of such an interaction is plastic fatigue..

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.