Introduction

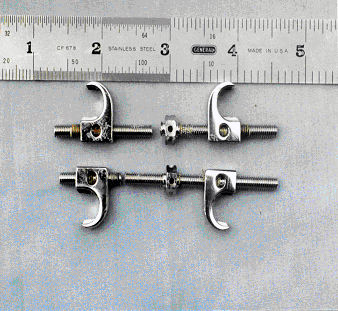

A failure analysis was performed on stainless steel back supports (Knodt Rod) that failed after being surgically implanted in a female patient. The Knodt Rods are used as an internal fixator for promoting fusion for repair of the lumbar spine. They consist of two hooks that are threaded onto a rod. One end has right hand threads and the other left hand threads. This allows the hooks to move in opposite directions when the rod is rotated. This allows the hooks to be spread apart with the turning of the rod.

Procedure and Results

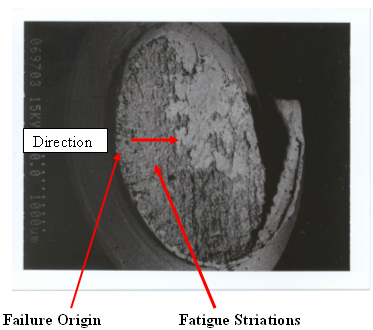

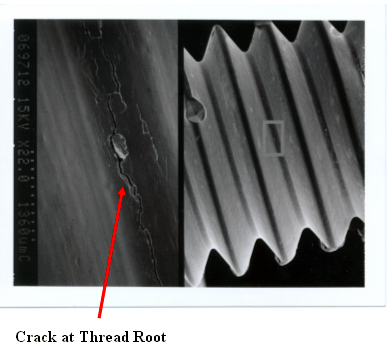

The subject Knodt Rod was examined visually and with a scanning electron microscope (SEM).

Figure #1: The two failed back support rods as received

Figure #2: Representative SEM macrograph of one of the four fracture surfaces created when the two rods failed. Both rods failed in fatigue. Both failures originated at the root of a thread.

Figure #3: SEM photomicrograph of threads on one of the Knodt rods. At left is a magnification of the root of the thread showing cracks at the root of the thread. This is the type of crack that initiated the fatigue failure (Mag. approximately 30X).

Discussion

The Knodt rods failed from fatigue cracks that initiated at the root of the threads. The simple explanation for this failure is that the part could not survive, over time, the working loads. This situation could be improved by increasing the radius at the root of the threads. Further study is required to determine further improvements.

I have these.

I have these. They have failed.

Sorry to hear! Please let me know if I can help.