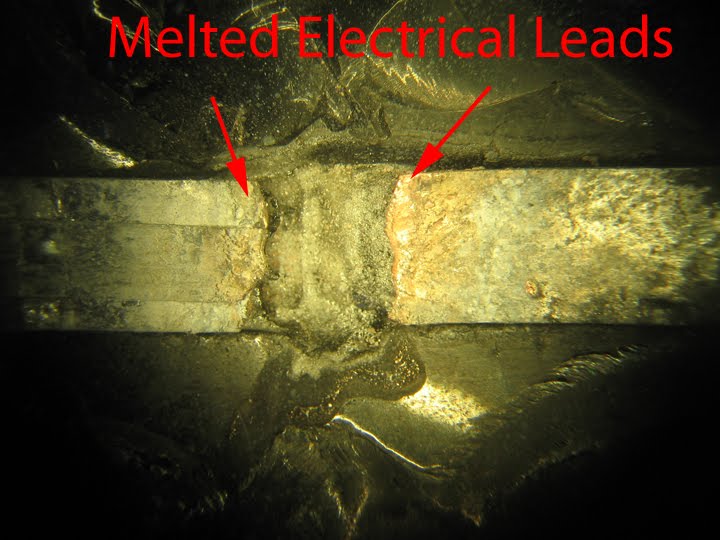

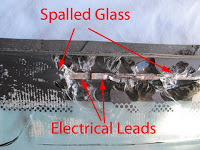

A failure analysis was performed on a light rail windshield failure. In this there was a pop and the operator was showered with glass. The glass failure analysis expert witness determined that there were two leads to the windshield defogger that were in proximity and because they were improperly wired, arcing occurred between them. The arcing generated heat and pressure that caused the glass to crack and spall locally. Upper left is a photograph of the damaged region of the windshield. Upper right is a closeup of the leads that arced. One can see that the lead ends are melted.

A failure analysis was performed on a light rail windshield failure. In this there was a pop and the operator was showered with glass. The glass failure analysis expert witness determined that there were two leads to the windshield defogger that were in proximity and because they were improperly wired, arcing occurred between them. The arcing generated heat and pressure that caused the glass to crack and spall locally. Upper left is a photograph of the damaged region of the windshield. Upper right is a closeup of the leads that arced. One can see that the lead ends are melted.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.