Read Consulting Failure Analysis Laboratory was engaged to determine the cause of failure of a 12 oz beer bottle. This bottle was said to have exploded and caused injury to a person. The explanation was that the bottle spontaneously exploded as it was being pushed into a cooler filled with ice.

Discussion

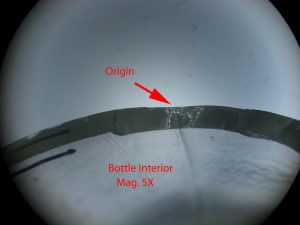

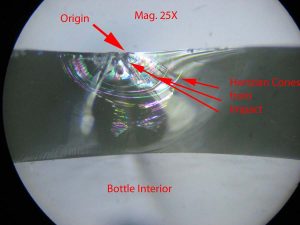

The cause of the failure of a bottle is determined by performing a root cause failure analysis. The standard procedure is to assemble the failed bottle, determine the general location of the failure origin, use markings on the glass fracture surfaces to locate the failure origin and microscopically examine the origin to determine the cause of failure.

Results Summary

The failure analysis above demonstrates that the bottle that caused the injury failed from impact damage on the bottle’s outside at the neck/shoulder region. Because the bottle was unopened the bottle’s gas pressure (approximately 40 psi) caused the initial cracks to grow rapidly . Essentially, the pressurized bottle “exploded” and pieces of glass ejected by the bottle injured a bystander. This bottle did not fail at the bottom as a result of it being pushed into a cooler filled with ice. It failed because it had been hit in the neck/shoulder region by a hard object when it was still under pressure .

Lesson: Do not toast with an unopened beer bottle. Open it first to relieve the pressure. Then you can toast!