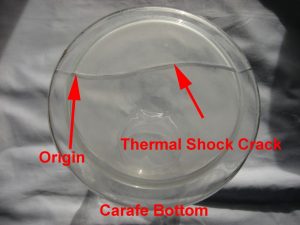

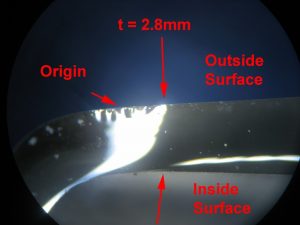

Read Consulting failure analysis laboratory was asked to examine a failed coffee pot that had been abraded with a cleaning pad and then subjected to a series of thermal shock cycles. The pot was heated to 190°C then immediately immersed in 10°C water. The pot appeared to survive till the 51st cycle. On this cycle a crack across the bottom appeared. Glass failure analysis performed on the fracture surfaces revealed a glass fatigue failure. The failure initiated at the location of abrasive damage and the flaw grew incrementally after each quench. It is unique to find actual fatigue in a brittle material. Apparently, the thermal shock stress was short term enough to allow incremental growth. Once the crack started, each quench caused the crack to advance and stop. The result is a crack arrest line.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.