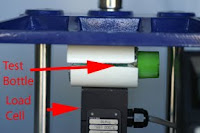

Glass failure analysis expert performed bottle strength tests to determine the strength of a cylindrical glass bottle. The bottle is approximately 0.85″ in diameter and 2.35″ tall. The glass thickness is approximately 0.040″ thick. It was hypothesized that a female could squeeze the bottle hard enough to crush it. Glass strength was measured by compressing the bottle both radially and axially. Upper left photograph shows the radial “squeeze test. The human hand is soft; therefore the test bottle was compressed between soft vinyl plastic tubing. In this orientation the bottle could withstand a minimum og 240 pounds force. The upper right photograph shows the “axial” strength test. Again, no hard surface touches the vial. Axially the bottle can withstand a minimum of 130 pounds. Even though the bottle may have many surface defects, it is strong because it is under compressive stresses. Because glass fails in tension, the cylindrical shape insures the highest strength. Because the bottle has no flat surfaces, it can withstand very high forces. No average female could generate sufficent forces with their hand to crush this bottle.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.

What if bottle had a bad annealing reading say 40° polariscope, no breakages seen at lehr, the bottle base thickness is 3mm, sidewall 2mm.

Is it safe to hold only the production and do 2nd reannealing?

Incomplete anneal can add tensile stress that will add to the applied stress and can aid breaking.