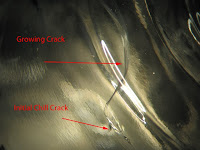

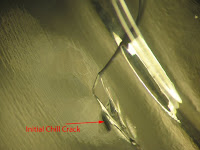

Glass failure analysis expert witness discusses a common glass bottle manufacturing defect. After the bottle has been formed it is removed hot from the clam shell tool. If it encounters any localized cooling at this stage, it can form a manufacturing defect called a “chill crack”. Thermal shock cause the cooled area to shrink, and this causes localized tensile stresses. This event can create a small crack that can cause later failure of the bottle. Above are two photos of the same chill crack. Upper left is a 20X photomicrograph, and upper right is a 40X photomicrograph. To start, this crack is less than 0.1″ long, and it has grown to be approximately 0.7″ long. The bottling line has had numerous failures from this lot of bottles, and the cause has been traced back to this type of chill crack.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.