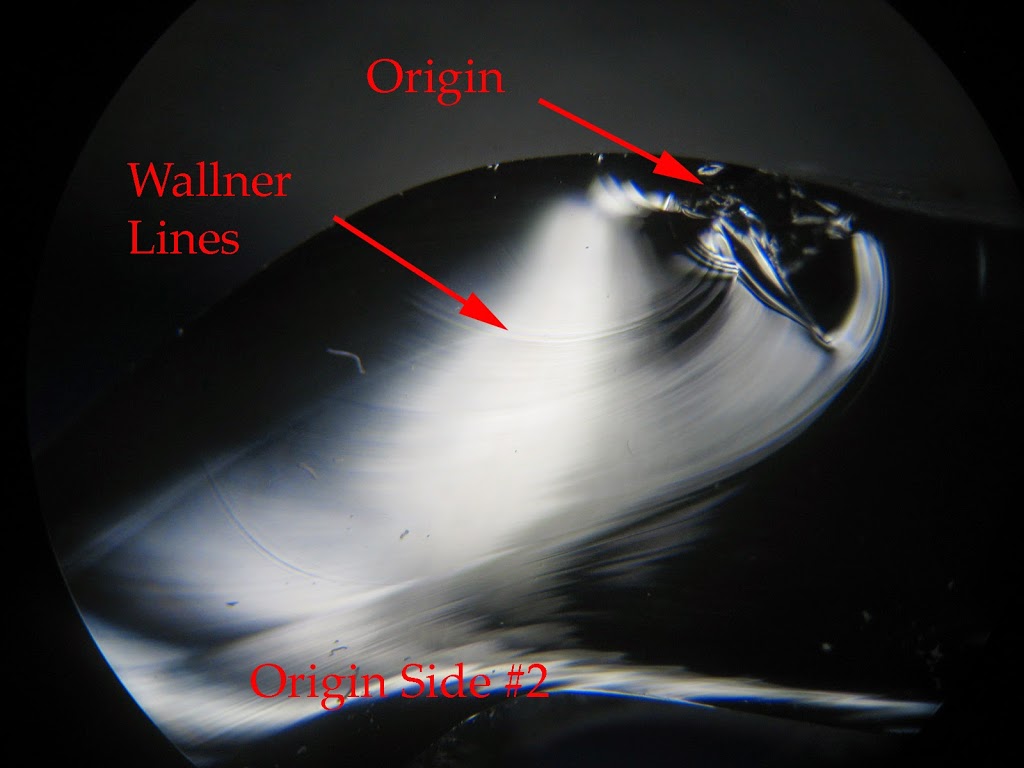

A Read Consulting glass expert witness performed a glass failure analysis of a glass crack driven by thermal stresses. The failed bowl cracked in a microwave oven. Often failures with known causes can be analyzed to lend insight as to the cause of an “unknown” glass fracture. This fracture has many of the aspects of an impact failure. However, the crack never reaches terminal velocity (i.e. there is no mist hackle generated). This glass failure initiated at a damage site on the bottom, bearing surface of the bowl. The bearing surface is the surface that would be in contact with a flat surface when the bowl was set down. On the left is an upside-down photograph of the bowl. The location of the origin is indicated. On the right is a photograph of the fracture origin on the fracture surface. This glass failure started where there was previous mechanical damage to the bottom of the bowl. The thermal stresses due to the microwave heating were high enough to cause failure as a result of the pre-existing damage. Absence of mist hackle is a key factor in this failure.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.