|

| Larger Point Impact (1/8″ Dia.) |

|

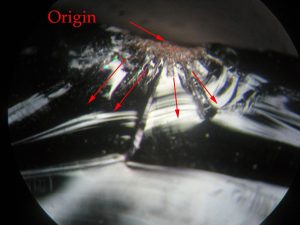

| Fracture Surface at Origin of 1/8″ at 40X |

|

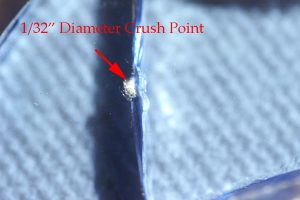

| Small Point Impact (1/32″ Dia.) |

|

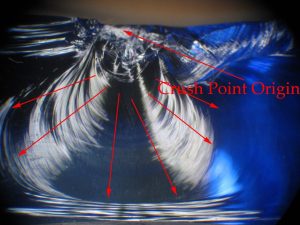

| Fracture Surface at Origin of 1/32″ at 40X |

Often bottles and other glass objects fail as a result of “point impact”. Given here are two examples of point impact failure origins discovered as a result of glass failure analysis performed at the Read Consulting Failure Analysis Lab. The origin is found by tracing the crack backwards on the fracture surface. Often there is a crushed glass region at the point of impact. This blog demonstrates two impact failures. Shown are the are both the impact point on the free surface and the origin as observed on the fracture surface as viewed at 40X using an optical microscope.