Read Consulting has lengthy experience aiding food processing companies by examining contaminants found by their customers. In many cases the product (such as tomato sauce) is packaged in polymer lined #10 steel cans. Obviously, the customer opens the cans and uses the contents for cooking. If the can opener isn’t sharp or is improperly aligned, it can produce steel material (i.e. swarf or turnings) that can accidentally go into their cooked meals.

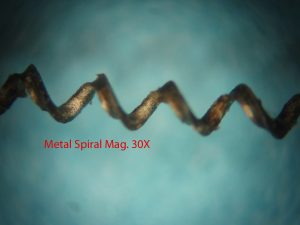

Below is a photograph of a sauce contaminant returned by a customer claiming that it was in the can of sauce. It was not clear exactly when the material was discovered. However, since this material was sent by the customer, an analysis was required.

In this case a pizza parlor returned a “contaminant”, shown below, claiming it had come from the can of sauce. Read Consulting was asked to determine the source of this material and whether it had been in the can.

Analysis:

- The “spiral” had a plastic coating that was removed and examined using FTIR. This was a match with the standard can interior polymer coating.

- Scanning electron microscope with Eds identified the spiral as mild steel.

Conclusion:

This material was not in the canned product when it was shipped.

This material was created by the can opener during can opening, and it got into the sauce and onto the pizza.