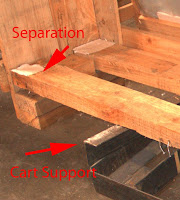

Failure analysis expert witness was asked to perform a root cause failure analysis of a wood shipping crate failure. It rolled over and caused a factory worker injury. The wooden crate in question was loaded with 3mm thick sheets of glass. This crate was designed such that there was a four-inch lengthwise gap in the floor. The center section consisted of two short spacers. Therefore, when the crate was loaded onto a standard glass shop cart, the center portion of the stack of glass sheets (estimated weight of 1200 pounds) was unsupported and could press down onto the skids and separate the front floor board from the skid. The upper left photograph shows one end of the crate and the support “fork” of the cart. One can also see that the front floor board has pulled away from the skid. The same thing happened on the other end. Here one can see that the “tensile” nails had pulled out. In addition, the “shear” nails were very near the surface and these separated from the floor board without bending. The shear nails do not meet ASTM D36097 which requires these nails to be centered on the floor board. These nails provided no strength to the floor board. This is a manufacturing defect.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.