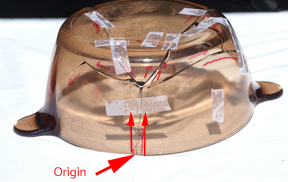

A failure analysis was performed on a broken 5 quart stove top glass pot. The origin was determined with optical microscopy, and the broken pot was assembled to show how cracking proceeded. The re-assembled pot is shown upside down in the upper left photograph. The failure originated at a preexisting “chip” on the interior at the top rim of the pot. In this case, the the Wallner lines indicated that, initially, the crack grew as a result of bending forces. Although the user had claimed that there was no impact involved in the failure event. The physical evidence indicates that this pot had been “bumped” on the outside near the top rim. It is important to realize that table top glass cook ware is just as fragile as normal annealed glass. It just has a much lower thermal coefficient of expansion. A large pot such as the one in this investigation is heavy, and a minor “bump” to the pot can generate high enough forces to cause failure and potential injury to one holding the pot. It is not unusual to have chips on the inner rim of such a pot due to the fact stainless steel spoons can be used to stir the contents. This failure analysis eliminated the possibility of a product defect or a manufacturing defect.

A failure analysis was performed on a broken 5 quart stove top glass pot. The origin was determined with optical microscopy, and the broken pot was assembled to show how cracking proceeded. The re-assembled pot is shown upside down in the upper left photograph. The failure originated at a preexisting “chip” on the interior at the top rim of the pot. In this case, the the Wallner lines indicated that, initially, the crack grew as a result of bending forces. Although the user had claimed that there was no impact involved in the failure event. The physical evidence indicates that this pot had been “bumped” on the outside near the top rim. It is important to realize that table top glass cook ware is just as fragile as normal annealed glass. It just has a much lower thermal coefficient of expansion. A large pot such as the one in this investigation is heavy, and a minor “bump” to the pot can generate high enough forces to cause failure and potential injury to one holding the pot. It is not unusual to have chips on the inner rim of such a pot due to the fact stainless steel spoons can be used to stir the contents. This failure analysis eliminated the possibility of a product defect or a manufacturing defect.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.