Introduction

A plumbing failure analysis was performed on a failed hot water shut off valve. As a result of the valve failure, water was sprayed in a second floor bathroom, and this caused extensive water damage to the home.

Summary of Results

The valve failed due to embrittlement of the acetal plastic valve stem. It is known that Acetal plastics will degrade and become brittle when exposed to the chlorides in chlorinated water. As a result, the subject valve stem deteriorated and failed. This is a design defect; the valve stem should have been made from a more durable material such as red brass.

Methods of Evaluation

The failed valve was examined visually and with a low power microscope. The fracture surface was examined with the low power microscope and with a scanning electron microscope (SEM). In addition, the composition of the “stem” of the valve failure was determined using Fourier transform infra-red Analysis (FTIR).

Results and Discussion

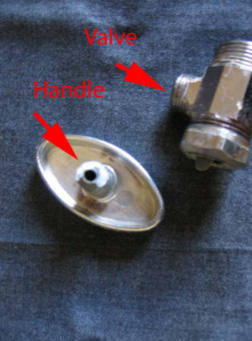

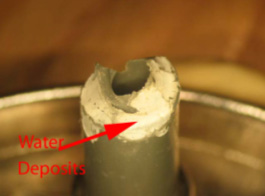

Visual and Low Power Microscope: Figure #1 is a photograph of the two pieces of the failed valve. It is apparent that the valve stem shows brittle failure. Figure #2 is a low power photomicrograph of the fracture surfaces of the failed valve stem. A plastic failure analysis was performed to determine the cause of failure.

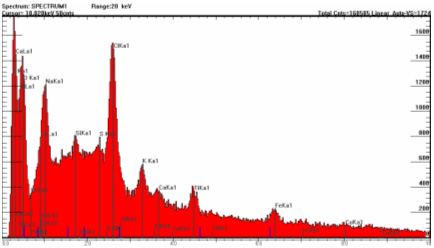

Scanning Electron Microscope (SEM) with Energy Dispersive X-Ray Analysis (EDAX): The shaft had two distinct fractures. An older fracture that is covered with scale from city water; in addition, there is a fresh torsion overload failure. The fresh failure happened long after the first fracture surface was created. The scale is also found on the outer surfaces of the valve body. This is an indication that this valve had been leaking for an extended time period.

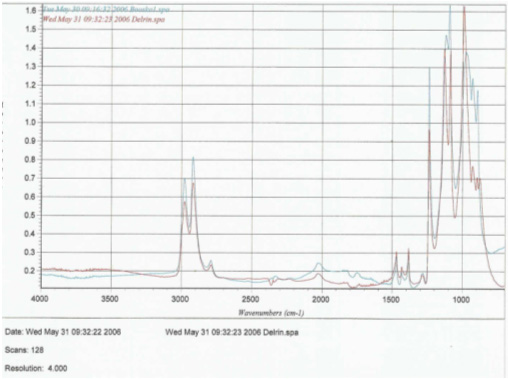

Fourier Transform Infra-red Analysis (FTIR): The FTIR analysis confirms that the valve post is made from acetal plastic.

Discussion

The initial crack in the hollow shaft allowed water to enter the center of the shaft. It appears as if the chlorides in the water degraded the Acetal plastic and made it brittle.

Figure #1: Photograph of the failed valve. The plastic valve stem failed in torsion overload.

|

|

| Mineral Deposit | Newer Fracture |

Figure #2: Photomicrographs of the fracture surface of the failed plastic valve stem. The photo on the left shows the portion of the fracture surface is coated with a white deposit. This is an indication that the coated fracture surface was an older fracture, and the valve had had a slow leak for an extended time period. The photo on the right shows the fresh final fracture; this is the final failure of the valve stem. (Approx. Mag. 10X).

|

|

Figure #3: SEM Photomicrographs of the fracture surface of the plastic valve stem. The photo on the left shows the portion of the fracture surface is coated with a white deposit. This is an indication that the valve had leaked for an extended time period. The photo on the right shows a fresh fracture. This is a torsion overload failure and it occurred long after the coated fracture surface was formed. This fresh fracture shows some plastic deformation; however, the initiation of the failure is brittle in nature (Approx. Mag. 20X).

Figure #4: Photomicrographs of the body of the valve. This is also covered with residue indicating that this valve had leaked for some time before the final overload failure (Approx. Mag. 10X).

Figure #5: EDAX elemental scan of the residue on the shaft fracture surface. The elements detected (Calcium, Chlorine, Silicon, Iron and Potassium) are compatible with residue from city water. The chlorides in the water are known to degrade acetal plastic.

Figure #6: An FTIR absorption scan of a sample taken from the plastic shaft. This is given along with a scan of a piece of Delrin (acetal plastic). The match shows that the valve shaft is made from Delrin (acetal plastic).

As a handyman, I have seen failures similar to this Acetal plastic valve stem failure. In one case, the “corrosion” (that’s what it looked like) occurred totally inside the valve such that the stem was eroded away to such an extent that water pressure alone pushed the outer portion of the stem and handle out through the packing and a full stream of water issued out flooding the house. There was no evidence of cracking or breaking and no external force acted upon it as the valve was behind a stack of towels that had been there for a long time.

When I went to purchase a new valve, the retired- plumber employee at Home Depot said that this type of failure was not a defective valve (except for the type of plastic, or that it was made of plastic) but that it was caused by some mineral in the water due to his experience of it occurring frequently in some areas (such as Peoria, AZ.) and not at all in others. He recommended that I replace all the stop valves in the house, which I did. I examined all of the replaced valves and observed that 3 others out of 12 had the beginnings of the same type failure, Not all the “corrosion” was in the stem area, one was in the screw-gear part and one was behind the washer. All “corroded” areas had the same white powder residue that you observed and tested.

Recently, I replaced a valve in a cold water line behind a toilet that was leaking due to the same type of “corrosion” of the valve stem inside the packing. This home is on a well water system and is not chlorinated.

Thank you for your observations. Deterioration can be caused by the combination of water contents and the type of polymer. Their is another type of attack on yellow brass called dezinc ification that will also produce a white powder (zinc oxide). Eventually the valve will lose strength and fail/