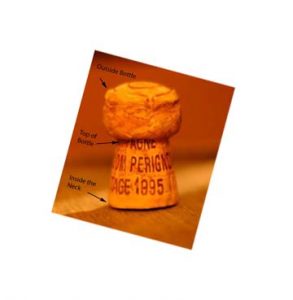

Background: The neck interior of all wine bottles is narrower at the very top than lower down in the bottle. The bottle interior is an inverted cone. So, due to cork expansion after bottling, the bottom of the cork is wider than the part at the top of the neck. This is how the cork seals the bottle. This is exaggerated for corks used for champagne and sparkling wines. These corks are highly compressed.

Champagne and sparkling wines are bottled at a pressure of approximately 90 PSI. For this reason a wire cage is used to hold the cork in the bottle.

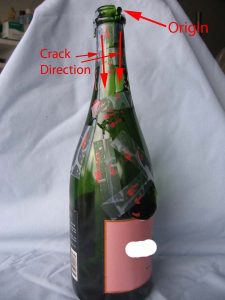

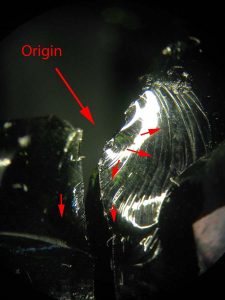

90 PSI is a reasonably high pressure and should be sufficient to push the cork out with some hand “wiggling”. In some cases the user will use a tool, such as a corkscrew or knife, to pry the cork out. In these cases, the bottle can be damaged, and this damage can cause the bottle to explode. The bottle failure is driven by the forces from the compressed cork and the internal gas pressure.

Below are photographs of a champagne bottle that exploded as a result of damage from a tool used to pry the cork out.