|

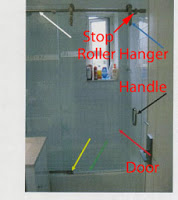

| Installed Shower Door |

|

| Top Roller at Stop |

|

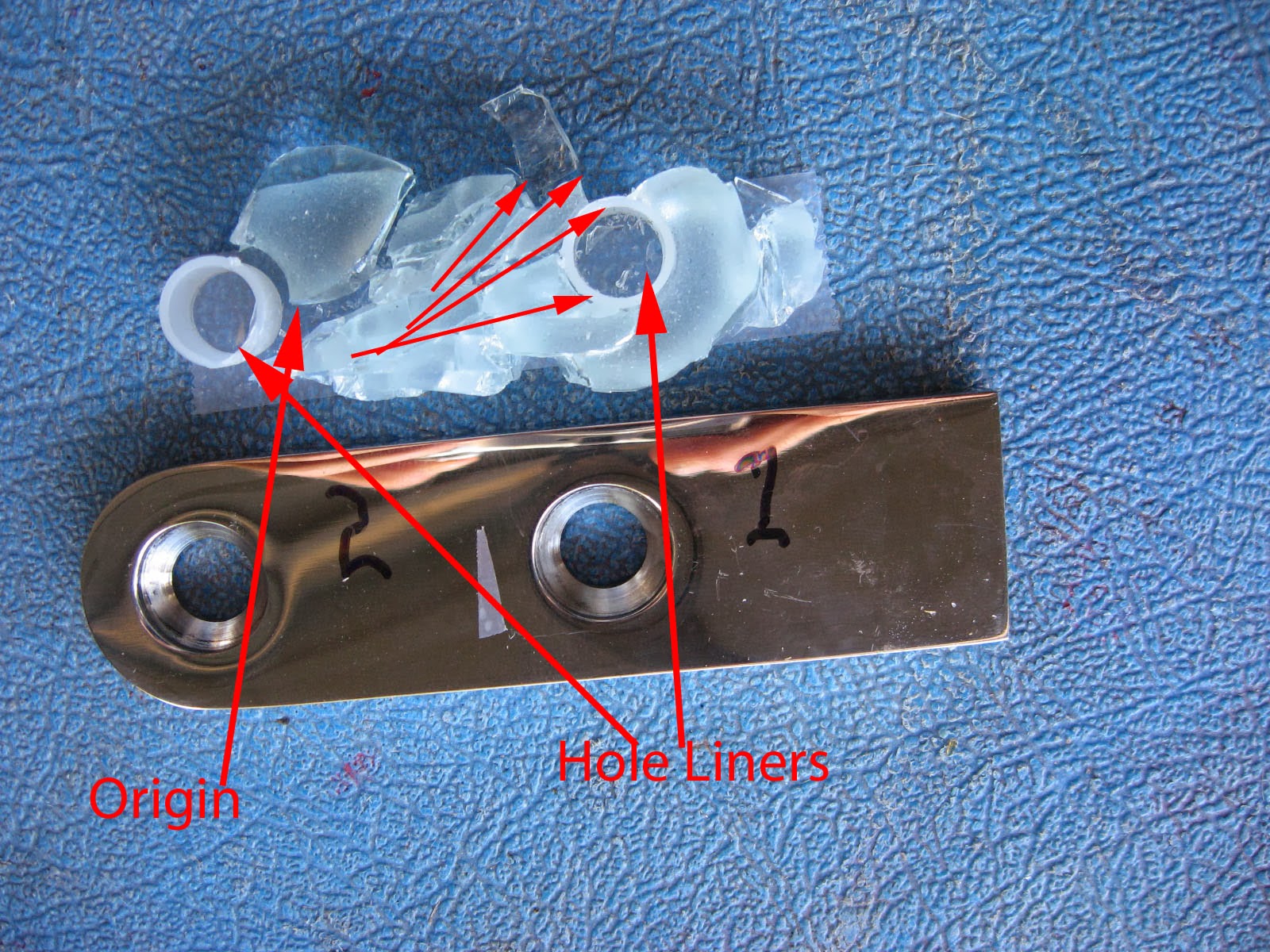

| Disassembled Roller |

|

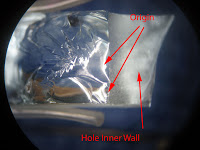

| Fracture Surface at Origin |

Tempered glass shower doors have been modernized. Recent designs have the doors suspended by rollers that ride on a pipe. In certain cases the door stop is on the top. In this case, the roller is stopped by a rubber bumper. Several of these doors had failed during use, and the glass experts at Read Consulting were asked to perform a failure analysis and suggest solutions to the glass fracture problem.

The two top photographs illustrate how these types of doors are installed. Basically they are hung on two rollers that are bolted to the tempered glass doors using holes cut into the glass. At the end of travel, these doors are stopped when one roller hits a rubber bumper. There is some cushion from the rubber bumper; however, this is not enough.

Glass failure analysis was performed on a representative failed door. In this case, the failure origin was clamped in one of the two rollers. The failure initiated on the interior wall of one of the through holes in the glass. It is believed that the failure forces are created by torsional moments generated because the top of the door is stopped, but the bottom of the door is not. When the door is stopped at the top, the unrestrained bottom creates a large rotation moment. This moment puts high forces on the walls holes in the glass. These forces act on the ground hole walls to cause failure.

The two lower photographs document the glass failure analysis. It is believed that the stopping mechanism must not generate twisting moments. One solution is to put the rubber stopper in the center of the door, not at the top. Another solution is to slowly reduce the door speed (i.e. create drag) before it hits the stop at the top.