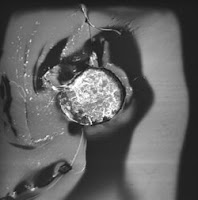

Glass expert performs a failure analysis on a failed tempered glass door. The spontaneous glass failure was analyzed to determine the cause of failure. This was one of several doors that failed spontaneously on a new high rise. Fortunately, the door did not fall apart; thus, the failure origin could be preserved. The upper left photo shows the failure origin (arrow). The origin was taken apart, and at the center was a spherical 180 micron diameter nickel sulfide particle, NiS particle. During the glass failure analysis, a scanning electron microscope, SEM, image of the particle is shown in the upper right. Elemental analysis of the particle showed it to consist of nickel and sulfur. The SEM image also shows initial Wallner lines that are spiral in shape and are leaving the particle. This identifies the NiS particle as the cause of the failure

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.