Introduction

A California failure expert was asked to determine the root cause of a rubber gasket leak. The molded rubber gasket was integrated into a hydraulic lift operating at 650 psi. Over time it had developed a very small hole and approximately 60 gallons of hydraulic oil escaped through this small leak. Read Consulting Failure Analysis Laboratory was asked to perform a detailed failure analysis to determine the cause of the leak.

Summary Conclusion

The subject molded rubber seal failed as a result of a rubber molding defect. During the molding operation there was a region where the flowing rubber failed to re-bond. Over time the high pressure (650 psi) hydraulic oil created a hole in the weakened rubber and this resulted into a rubber failure and a hydraulic leak.

Inspection Procedure

The exterior of the rubber seal failure with the small hole was examined with a low power microscope. The seal was then turned “inside out” and again viewed and documented with the low power microscope.

Results

Figure #1 shows two views of the rubber seal’s exterior. It is a 2”/ 60.3 mm gasket style rubber seal. The rubber is approximately 0.075” thick. Figure #2 shows the defect (i.e. pin hole) on the rubber seal’s exterior. The hole is on one of the two high ridges on the seal exterior. This seal failure appears to have originated from the interior of the rubber seal. Figure #3 shows the rubber defect (i.e. hole) on the interior surface of the seal. The hole appears to be in a region where the injection molded rubber is still in layers. The layered appearance indicates that there was a rubber molding defect in the region where the pin hole developed.

|

|

Figure #1 shows an two views of the rubber seal’s exterior. It is a 2”/ 60.3 mm Gasket Style seal. The rubber is approximately 0.075” thick. The leak occurred on one of the two ridges on the seal exterior.

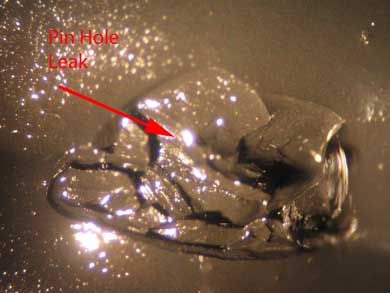

Figure #2 shows the pin hole defect on the rubber seal’s exterior. The hole is on one of the two high ridges on the seal exterior. This defect originated from the interior of the rubber seal. Please note that there is a missing layer of rubber in the region of the leak. In addition, the puffy nature of the hole indicates that the leak opens from the inside out. This photograph was taken with a low power optical microscope at a magnification of approximately 30X.

Figure #3: View of the pin hole leak after the seal has been turned inside out. This is a view of the pin hole defect on the interior surface of the seal. The hole appears to be in a region where the injection molded rubber is still in layers. The layered appearance indicates that there was a molding defect in the region where the rubber seal leak had developed. Photograph taken with a low power optical microscope at a magnification of approximately 40X.