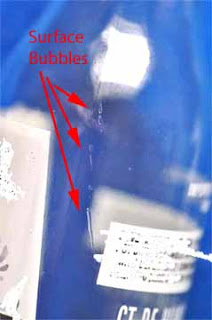

California failure analysis expert witness discusses bottle defects that can affect the bottle strength. In this case there are a string of bubbles in the glass that are mear the surface. There are cases where these bubbles have reached the surface and have opened. This will weaken the bottle by generating stress risers and thinning the glass locally. Due to hoop stresses, the strength of the bottle is directly proportional to the glass thickness, there are cases where this type of defect can significantly reduce the glass thickness and the bottle strength. This is particularly important in the case of beer and sodas, where the bottle contents are under pressure (54 to 50 psi). In this case the bubbles have not surfaced, thus the effect on the bottle strength is not as severe.