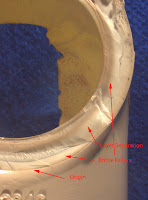

Plastic failure expert performs a failure analysis on a failed CPVC 90° 3/4 inch elbow. This elbow was in a 150°F hot water recirculation system in a large facility. Plastic fatigue was the alleged cause of failure. However, a plastic failure analysis found no evidence of fatigue. Instead, the detailed root cause failure analysis indicated that this elbow had molding defects and had deteriorated in service; in the top left photograph, one can see that the CPVC inner and outer surfaces have turned brown. The failure originated at a stress concentration point caused by the interior 90° angle. It initiated as a brittle fracture on the outside. It then became an overload failure in mid thickness. Finally, there were layer separations toward the interior of the elbow. The photo on the right is of the vent hole. This shows that the CPVC came out in layers. Thus, during plastic molding, there were layers of CPVC that did not “recombine”. Given that this elbow is formulated to operate continuously at 180°F, this elbow was a defective product due to both plastic molding defects and plastic formulation problems.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.