Galvanizing is the process of coating steel with zinc (Zn). The zinc is anodic with respect to steel; therefore, it will sacrifice to the steel in a corrosive environment. This means that the zinc will preferentially corrode and protect the steel, but this process is sacrificial. This protection will only last as long as Zn is present. Once the Zn is consumed, the steel is no longer protected and it will corrode accordingly. This is why old barns have rusted roofs. This means that the Zn thickness dictates the life of a nail. There are two types of galvanized nails; these are the following:

- “Hot dipped”: Here the steel nails are dipped in liquid Zn.

- “Electro galvanized”: In this case the zinc is electroplated onto the steel nails.

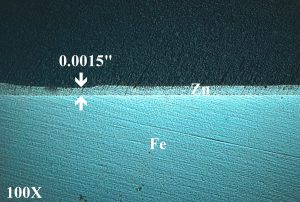

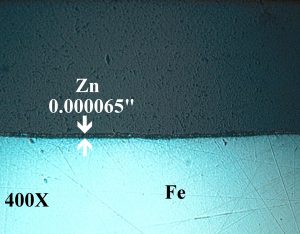

Samples of these two types of nails were examined to determine the Zn thickness. As shown below, the hot dipped Zn layer is much thicker and offers much longer protection.

information about the corrosion of two types of galvanized nails is a good and also useful information . thank you.Brainstorm Infotech is headquartered in Bengaluru, the start-up capital of India. It has carved a niche for itself in the field of structural steel detailing and allied services with a credit of completing over 1250 projects so far. We started small with a team of five professionals in 2010 but have earned the trust and respect of our clients that has led to long-standing associations.

Thank you!

Really it is all about the thickness of the zinc.