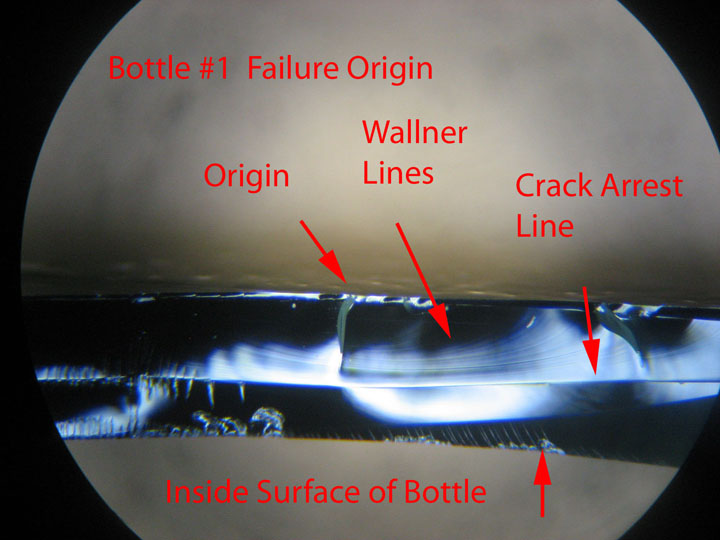

A bottling line for sparkling drinks was suffering from a high rate of bottle failures on the bottling line. In addition, several bottles failed on the shelf after bottling. Read Consulting was asked to perform a glass failure analysis to determine the cause of failure of three bottles that had failed “on the shelf”. Two of the three bottles were from the same mold cavity, and both failed at the exact same height from the base (2 1/4″). The third bottle failed at 2 1/2″ above the base. All three failure origins were the same. All three failures started on the outside of the bottle. All three had “crack arrest lines ” near the origin. In addition, All three had no visible mechanical damage to the bottle exterior at the origin. The presence of the crack arrest line confirms a delayed failure. These factors indicate that the failures are caused by defects caused by the bottle manufacturing process. This is a manufacturing defect that must be corrected by the bottle manufacturer.

Materials Failure Analysis and Process Engineering

You are here: Home / Failure Analysis / California Glass Expert Performs a Failure Analysis of Sparkling Liquor Bottle Failures

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.