Stainless steel corrosion failures often result from grain boundary sensitization. Many 300 series stainless steel alloys come in two grades or more. For example 304 stainless steel comes as 304, 304L and 304H. Each grade has a different amount of carbon (C). the 304 grade allows up to .0.08% C; whereas

304 L allows a maximum of 0.03% C. In corrosive environments, this is critical if the piece is welded or heated in the temperature range from 459°C to 850°C. As the carbon content increases in the alloy, the time for grain boundary sensitization decreases. Grain boundary sensitized stainless steels exhibit rapid corrosion failure at the grain boundary because the chrome has been tied up by the carbon in the grain boundaries.

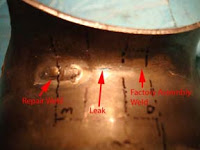

In this case the California failure analysis expert performed a corrosion failure analysis on a jacketed pipe made from 304 stainless steel which corroded rapidly as a result of grain boundary sensitization. The alloy was not specified correctly. The design drawings should have specified solution treated 304L or 316L plate for the manufacture of the industrial pipe. The plumbing failure expert contends that if this were done, the plumbing failure would not have occurred. The equipment designer cannot rely on the supplier to pick the proper materials..