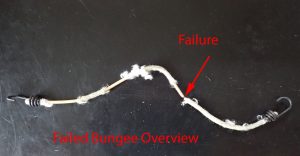

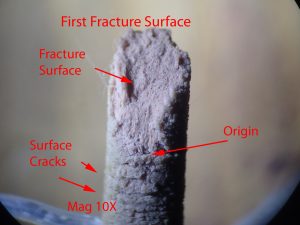

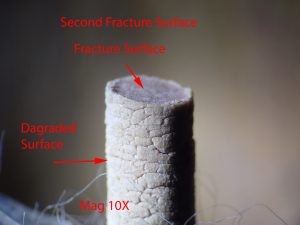

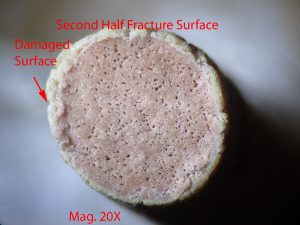

Bungee cords are often used to secure cargo. However, they can fray and age. The cloth cover can open up and allow UV degradation of the rubber inside. In addition, heat can also cause the interior rubber to degrade. Before using a bungee cord, be sure to examine it to be sure it is in good working condition. Below is a series of photographs of a failed bungee cord. In this case the cloth cover was frayed, and the interior rubber had dried and cracked.Curiously, at the point of failure there are 2 distinct failure surfaces, which are shown below. There is a missing piece at the origin.In both recovered origins, the rubber surface is brittle, and the cracking initiated on the surface. Fair warning not to use an old bungee cord for securing a load.