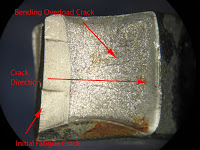

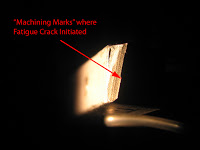

California failure analysis expert performs examines a failed cutting tool. In this case the cutting tool consisted of a carbide cutting tip brazed to a mild steel “post”. The failure of the post initiated as a fatigue crack at a grinding mark where the post was shaped to accept the carbide cutting tip. The final failure ended as a 45° bending overload. The failure was caused by high machining forces caused by the absence of lubricant. The upper left photomicrograph is an overviewof the fracture surface. It shows the two phases of the crack. Upper right shows the grinding mark where the fracture initiated.

California failure analysis expert performs examines a failed cutting tool. In this case the cutting tool consisted of a carbide cutting tip brazed to a mild steel “post”. The failure of the post initiated as a fatigue crack at a grinding mark where the post was shaped to accept the carbide cutting tip. The final failure ended as a 45° bending overload. The failure was caused by high machining forces caused by the absence of lubricant. The upper left photomicrograph is an overviewof the fracture surface. It shows the two phases of the crack. Upper right shows the grinding mark where the fracture initiated.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.