Read Consulting was engaged to perform a glass fracture analysis on a broken clothes washer door failure. The glass is 5mm thick heat strengthened glass. It was claimed that the glass failed “spontaneously” and caused an injury. Examination of the glass remaining on the door revealed that the glass failed from impact. There is a partial origin where the glass was impacted. Fully tempered glass (minimum surface compression of 10,000psi) has been known to spontaneously fail. Heat strengthened glass (surface compression of 3500psi to 7500psi) does not.

Figure #1: Photograph of failed door.

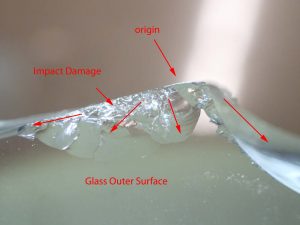

Figure #2: Photo-micro graph of the preserved portion of the failure origin. Although the entire failure origin was not preserved, the remaining part shows severe impact to the glass. (Mag. 15X).

Figure #2: Photo-micro graph of the preserved portion of the failure origin. Although the entire failure origin was not preserved, the remaining part shows severe impact to the glass. (Mag. 15X).

Front View Figure #3: Photographs of a representative new clothes washer door. The door glass is a 5mm thick “cupped shaped” piece of heat strengthened glass. The convex portion of the glass reaches into the washer.