California glass expert discusses the importance of edge finish on tempered glass. Tempered soda lime glass has replaced low expansion borosilicate glass for small oven doors and glass tops for cookware. This reduces costs, but can reduce reliability. One important aspect of these tempered glass pieces is the edge quality. Poor edge finishing can introduce defects that can cause eventual failure.

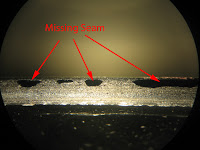

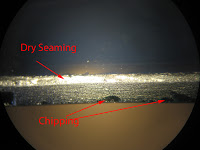

There are three common edge defects. These are chipping, missed seaming and “dry” seaming. Normally these pieces are scribed and broken, seamed with a wet belt sander and tempered. These three edge defects are illustrated by the figures. Read Consulting failure analysis lab has looked at numerous tempered glass failures that have originated at the edge; thus, edge finish is extremely important for any glass piece that can be preferentially heated in the center.

There are three common edge defects. These are chipping, missed seaming and “dry” seaming. Normally these pieces are scribed and broken, seamed with a wet belt sander and tempered. These three edge defects are illustrated by the figures. Read Consulting failure analysis lab has looked at numerous tempered glass failures that have originated at the edge; thus, edge finish is extremely important for any glass piece that can be preferentially heated in the center.